Cocoa Reduction Tools & Strategies

Technologies

Solve the

Cocoa

New ingredients, angles, options to extend or replace chocolate

Challenge

By Erin Costello

by Kantha Shelke, PhD, CFS, Contributing Technical Editor

Video credit: iStock/Vadym Terelyuk;

Two-thirds of the world’s cocoa, derived from the fruit of the cacao tree (Theobroma cacao) comes from two equatorial West African countries, Ivory Coast and Ghana, a precariously narrow geographic region. This leaves the global supply of chocolate’s key ingredient highly vulnerable to a multitude of impacts, including climate change, disease, political strife, outdated agricultural practices, blight, and supply chain disruptions.

These challenges already have caused lower cocoa yield and supply instability, leading in turn to quality and safety concerns such as heavy metal and pesticide contamination from archaic farming and handling practices. Meanwhile social and environmental issues including child labor, economic inequity, and high-carbon-emission transportation methods tied to unsustainable farming practices are compounding these interconnected issues.

Cocoa Power

Cocoa powder—celebrated for its many sensual qualities, nutritional properties, and neurostimulant effects—is challenging to replace entirely. However, a combination of bioinformatics, fermentation, roasting, and blending techniques offers promising avenues. The current ingredient crisis also highlights the opportunity to expand beyond cocoa, tapping into a broader diversity of crops abundant in bioactives, phytochemicals, and nutrients.

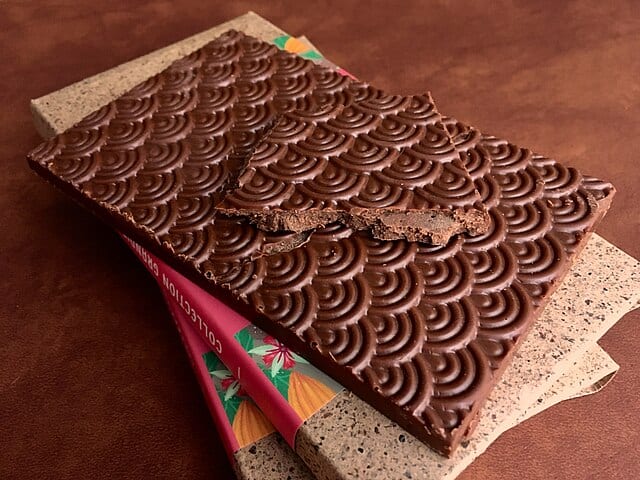

Replacing cocoa—partially or entirely—requires a deep understanding of cocoa’s complex characteristics and multifaceted role in formulation and processing. Credit: T. Hasegawa USA, Inc.

All these challenges underscore the need to stabilize the cocoa supply through enforcing sustainable practices, creating equitable supply chains, and applying science-backed innovations that ensure stability and affordability without compromising quality. In response, the food industry is exploring innovative solutions to address all these challenges and their associated rising prices.

This “perfect storm” is spurring efforts to extend, enhance, or replace cocoa while preserving the distinct qualities that make chocolate the premier globally loved ingredient. The cocoa crisis forces suppliers and manufacturers to innovate or adapt. Suppliers are prioritizing competitive, lower-cocoa-content products to maintain market share, while manufacturers are recalibrating their strategies to mitigate costs and meet consumer expectations.

Key approaches include optimizing cocoa use and adjusting formulations to use less cocoa without compromising quality; reprioritizing portfolios by focusing on high-performing brands and discontinuing underperformers; and developing alternatives by exploring cocoa replacements via extenders, enhancers, or eliminating cocoa entirely (creating analogs).

Want to know more about chocolate? Check out the following articles and multimedia offerings:

“Bon Voyage” (video) >> click here

“How to Boost Chocolate Flavor, Reduce Cocoa, and Cost” (article) >> click here

“Formulating With Chocolate” (video) >> click here

“Sweet & Green: Plant-Based Chocolate” (article)

>> click here

“Sugar Reduction's Ultimate Test: Chocolate” (podcast) >> click here

“New Applications for Chocolate and Vanilla Ingredients” (article) >> click here

“20 Degrees of Flavor: Chocolate and Vanilla” (article) >> click here

“Chocolate, Chocolate, Vanilla!” (article) >> click here

Finely powdered, dark toasted malts provide texture, depth, and bittersweet flavor notes similar to cocoa at replacement levels up to 25% in some formulations. Credit: Briess Malt & Ingredients Co.

Innovation and Recalibration

Replacing cocoa—partially or entirely—requires a deep understanding of cocoa’s complex characteristics and multifaceted role in formulation and processing. Cocoa contributes flavor, texture, viscosity, and sensory experiences, all of which must be replicated as precisely as possible for successful outcomes.

Emerging solutions address these challenges with one-to-one cocoa replacements suitable for full chocolate bars, and customized solutions designed for smaller format products such as chocolate chips or syrups in applications where chocolate is a secondary sensory component. This dual approach enables seamless market integration while minimizing consumer focus on novelty, thereby encouraging faster adoption.

Allergen-free chocolate analogs derived from ingredients such as upcycled grapeseeds are replicating identical flavor and texture of the original with uncanny accuracy. Credit: Voyage Foods, Inc.

The bulking and texture functionalities from cocoa solids add viscosity and moisture absorption. But cocoa also carries aromatic diversity, as it contains more than 400 aromatic compounds that contribute to its distinctive aroma and flavor. The rich sensory eating experience of finished chocolate derives from how its fat content influences mouthfeel and flowability. Most specifically, cocoa butter has a melting point similar to human body temperature. These qualities give it an almost addictive mouthfeel.

Making a product that looks, tastes, and has a mouthfeel like chocolate without using cocoa involves matching these functionalities through fermentation, roasting, blending, and bioengineering techniques. Innovators have made great strides with ingredients such as grapeseeds, fava beans, pomegranate, and others, and technologists are now exploring additional sources such as acorns, jackfruit seeds, oats, and upcycled plant streams to replicate cocoa’s various qualities.

Holistic solutions are being developed to maintain the desired mouthfeel, richness, and overall characteristics of products like chocolate chip cookies by using cocoa extracts, natural or artificial flavors, and other tailored ingredients customized to specific cost and formulation goals. Such an approach can help replace as much as a third of the cocoa in bakery products like cookies and brownies.

Chocolate-Free Voyage

Voyage Foods, Inc. added chocolate-free, dairy-free, and nut-free “chocolate-hazelnut” spread to its line of allergen-free peanut butter analogs. The company uses cocoa-free chips and melting wafers that it crafted through proprietary technology. Derived from ingredients such as sunflower seeds, chickpeas, and upcycled grapeseeds the spread is identical in flavor and texture to popular chocolate-hazelnut spreads on the market—a boon to those with nut and dairy allergies.

Dark caramel colors add an attractive depth to chocolate sauces, coatings, and fillings, and add visual appeal to chocolate products using less cocoa. Credit: Sethness-Roquette/Sethness Products Co.;

Strategic Reduction

Reducing cocoa in products by pivoting to milk or white chocolate, is another strategy. While dark chocolate manufacturers justify higher price points due to health benefits, artisanal chocolatiers face challenges in balancing costs and quality.

Supporting the search for an ideal cocoa substitute are both traditional and novel approaches. The Olmecs, Mayans, and Aztecs valued cacao for energy as well as its bioactive and medicinal properties. Similarly, indigenous societies have relied on diverse local plants rich in bioactives. Today’s ingredient crisis highlights the opportunity to expand beyond a narrow range of crops to untapped plants abundant in phytochemicals and nutrients, offering immense potential for sustainable innovation. High-tech methodologies leverage historical literature and traditional practices to offer valuable possibilities.

Although largely ignored in the US, acorns are traditionally featured in global cuisines for bread, cakes, porridge, soups, coffee-like drinks, and desserts. With a cereal-like composition (31-51% carbohydrates, 8-9% protein, 7-9% fat) and high nutritional value (magnesium, calcium, B vitamins, dietary fiber, unsaturated fatty acids, and polyphenols), acorns can be used to create cocoa powder substitutes suitable for sweet baked goods.

Reshaping the Farmer-Consumer Relationship

Artisanal chocolate-making companies are reshaping the farmer-consumer relationship to foster sustainability and equity within the chocolate industry by crafting chocolate bars with cacao beans directly procured from the growers. In addition to showcasing the merits of their single-origin cocoa, programs include other eco-friendly methods. These include planting a cacao tree for every chocolate bar sold. This not only promotes environmental sustainability, it enhances biodiversity in the regions where the trees are grown. Other methods employed are conducting workshops to educate growers on sustainable agriculture and advanced farming techniques, and purchasing cacao at fair and premium prices to ensure a living wage and opportunities for expansion and knowledge-building in cacao farming. Notable bean-to-bar companies include:

Askinosie Chocolate, LLC

Dandelion Chocolate, Inc.

Fruition Chocolate Works Co

Goodnow Farms Chocolate, LLC

GoodSam Foods, Pbc

K'UL Foods, LLC

Moka Origins/Soma Direct Trade LLC

Carob powder, from the pods of the locust bean (Ceratonia siliqua), is a common cocoa replacement. Carob is rich in antioxidants and minerals (potassium, calcium, sodium, and magnesium) and free of stimulants, making it ideal for gluten-free, dairy-free, and low-fat applications. Even so, the flavor has not proven sufficiently close enough to cocoa for it to have wide consumer acceptance as a true substitute.

A cousin of cacao, cupuaçu (Theobroma grandiflorum), makes an excellent chocolate-like substance, although its flavor is closer to mocha—chocolate with a faint back note of coffee. The texture and mouthfeel of chocolate bar substitutes made from it are virtually identical to true chocolate, but they have a light rose-brown color. Still, this chocolate substitute has high acceptance among consumers. It is an expensive ingredient however and hard to cultivate.

Dark malted flours are a way to bring both richness of flavor and color into a chocolate formulation to replace up to 25% of cocoa, depending on the product. So, too, dark sweet syrups from sources such as sorghum, corn, rice, barley, and even dark caramel can add sweetness, color, and depth of flavor that can fill in for smaller percentages of cocoa. All these require careful incorporation, as consumers will be unforgiving if a formulation deviates more than the slightest from expected cocoa and chocolate flavors.

Achieving consumer-expected characteristics of products like chocolate confections with less chocolate calls for synergistic combinations of ingredients customized for both formulation and cost goals. Credit: PROVA US, Inc.

Bioinformatics and Biotechnology: New Frontiers

Chocolate does not grow on trees. It is the product of careful fermentation and roasting of cacao pod beans to bring out the characteristic aroma, flavor, and overall texture so favored by consumers. Innovators are exploring ways to produce a similar product by fermenting and roasting other raw materials, such as the aforementioned acorns, oats, jackfruit seeds, and apricot pits, as well as olive kernels and even potato peels.

The underlying objective for this approach is to remove reliance on a single crop or a single region and to take advantage of a variety of crops, and possibly even food waste. Through technology, the goal is to convert molecules biochemically similar to those in cacao into a cocoa-like ingredient using the traditional methods of fermentation, roasting, blending, and further biotechnology.

Advances in bioinformatics and synthetic biology are transforming how alternatives are developed. For example, one biotechnology company is using a registered AI-powered platform that explores the so-called “dark matter” (unexplored biochemical components) of the plant kingdom to identify bioactives and map their potential human health benefits. This pioneering company has mapped more than four million compounds, offering unprecedented insights into viable cocoa alternatives.

The strains of cocoa shortages in Africa are bringing more pressure on South American sources where the focus is on sustainability and fair trade. Credit: Casa Luker, SA

From Alt-Cocoa to the Future of Chocolate

Much of the flavor and functionality of chocolate comes not from the cocoa bean itself, but from how it is processed (fermented, roasted, blended). Some cocoa analog companies are relying on applying this technology to other plant sources, while others are combining these classic methods with cutting-edge methods, such as cellular fermentation and cellular agriculture. Examples include the following:

- California Cultured, Inc. extracts and grows cells from cacao in condition-controlled tanks that replicate their natural ‘rainforest’ environments in just three days vs. months for cacao harvesting—but without the precariousness, carbon footprint, or reliance on deforestation.

- Nukoko, Ltd. uses a scalable biotransformation technology replicating the fermentation process that typically is used to transform cocoa beans into chocolate but with fava beans native to the U.K. instead of cocoa beans. The technology could be adapted to other regional raw materials globally, eliminating the need to ship ingredients between countries.

- Planet A Foods, GmbH uses precision fermentation with yeast, oats, and sunflower seeds to emulate cocoa flavor and functionality and produce cocoa-free chocolate, plus cocoa-free/palm-free lipid to replace cocoa butter in chocolate applications.

- W!nWin Food Labs, Ltd. applies traditional fermentation techniques to spent barley and carob to produce vegan, caffeine-, palm-, gluten-, and cocoa-free analogs of chocolate bars and chocolate chips for consumers. The products also are lower in sugar and manufactured more sustainably than their true chocolate counterparts, generating significantly lower carbon dioxide emissions.

Other companies, such as the Israeli biotech enterprises Circe Bioscience, Ltd. and Kokomodo, Ltd., are leveraging synthetic biology to convert gases such as hydrogen and carbon dioxide into cocoa-like ingredients (Circe) and employing microbes in cellular agriculture (Kokomodo) to make cocoa isolates, presenting a sustainable and scalable solution. Another Israeli biotech, Celleste-Bio, Ltd., is “using a three-pronged model” of biotech, agritech, and AI to produce 100% natural cocoa ingredients at scale.

As climate change-related risks and more elementary disruptions persist, the food industry’s ability to innovate and embrace alternatives will determine how it navigates the cocoa crisis. Fortunately, intrepid ingredient experts are using—and even creating—next-generation technology to ensure that chocolate’s future will remain as rich and satisfying as its past.

Kantha Shelke, PhD, CFS, is a senior lecturer at Johns Hopkins University and principal of Corvus Blue LLC, a Chicago-based food science and research firm specializing in industry competitive intelligence, expert witness services, and new product/technology development and commercialization of foods and food ingredients for health and wellness. Contact her at kantha@corvusblue.net.