New Products

Ingredients

cannabis products

Packaging

Table of Contents

Equipment

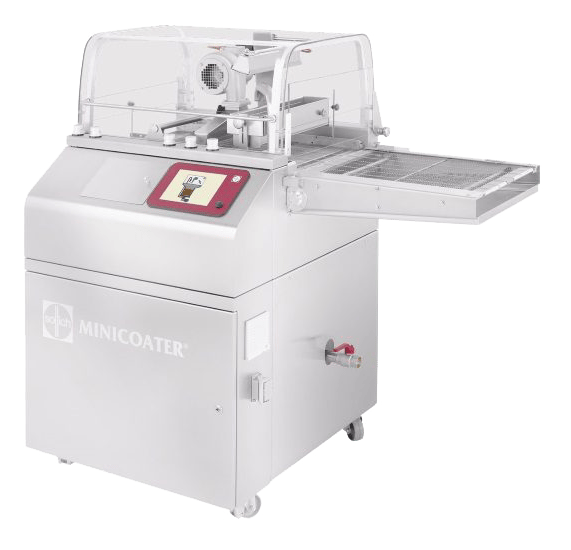

Equipment Snapshot: Several improvements have been made to previous generations of TTS enrobers, paving the way to Sollich's newly developed Minicoater MC 420.

This enrober is a small-scale chocolate coater with a built-in chocolate tempering system. The new Minicoater has a separate frequency-controlled drive for the bottoming roller and a removable wire tensioned detailer system. This enrober comes in either a 12- or 16-inch-wide wire belt. It has a capacity of 120 kg per hour.

Equipment Snapshot: The ROSS Inline Ultra High Shear Mixer 700 Series is designed for challenging shear requirements, serving as a more efficient alternative to colloid mills, which generally suffer from low throughput.

Depending on the application, it can replace high-pressure homogenization or serve as a pre-mixer to high-pressure homogenizers to mitigate clogging and inconsistent feed quality issues. To meet the specific demands of niche processes in the food, beverage and pharmaceutical industries, ROSS developed the QuadSlot rotor/stator for demanding applications where conventional rotor/stator mixers fall short but do not require the intensity of other ROSS 700 Series ultra-high shear designs.

By exposing product to four successive stages of increasing shear, the QuadSlot often provides a perfect balance of shear and flow capacity in the inline processing of emulsions, agglomerate size reduction, and gas-liquid mixing. The washdown-duty Model HSM-706Q-40 features a 40-horsepower motor with a 6-inch QuadSlot rotor that runs at tip speeds over 11,000 fpm. This mixer is easy to clean and sanitize in place, saving time and allowing for longer production runs.

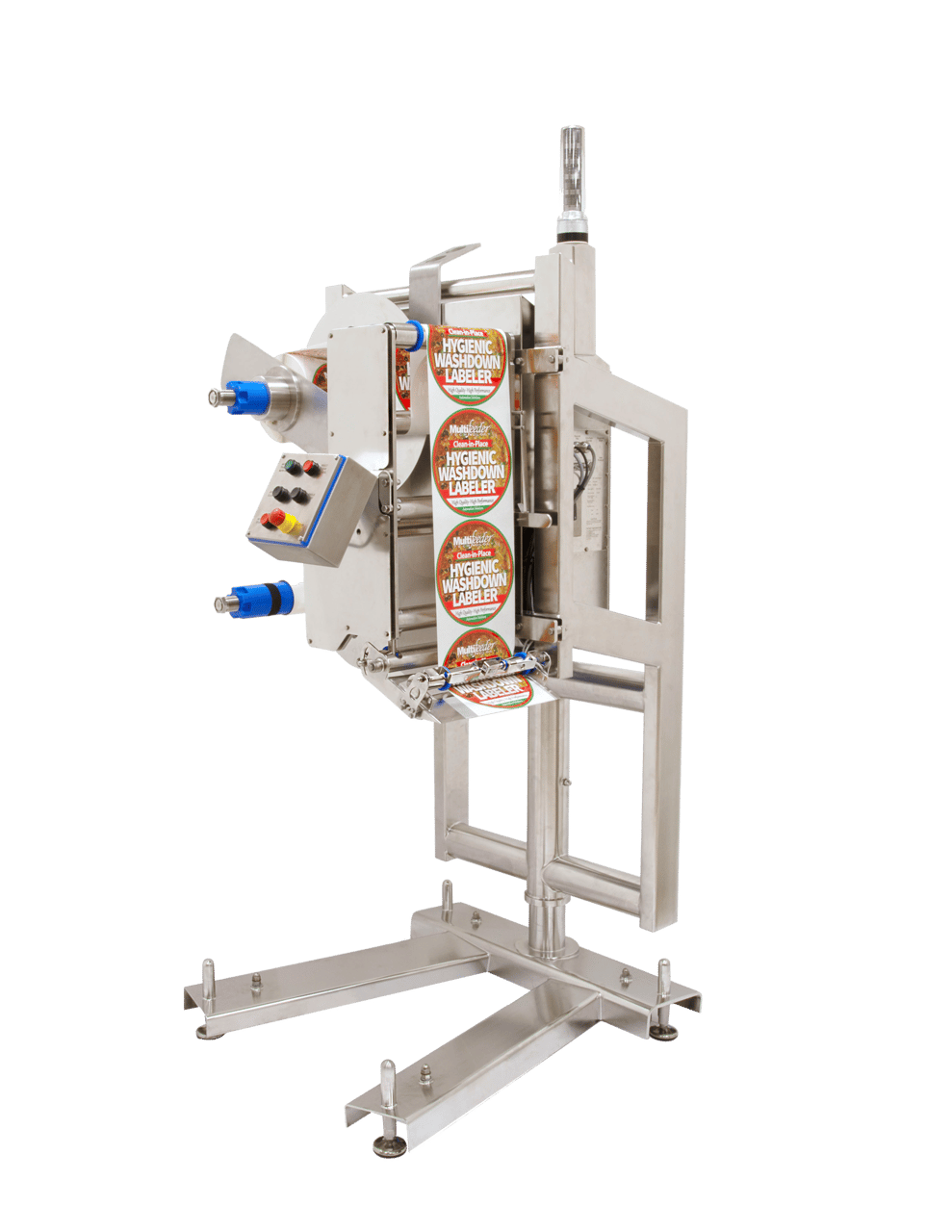

Equipment Snapshot: The Hygienic Washdown Labeler is engineered with 304 stainless steel and passivated for corrosion resistance. The labeler's clean-in-place design provides minimal contamination points. This allows for minimal disassembly with easy cleaning and maintenance, reducing risk of contamination on the factory floor. The labeler is mobile, utilizing a small footprint to quickly change workstation locations and be easily cleaned on the factory floor.

Other features include the computer-controlled brushless servo motors for flexible high-speed accuracy, precisely placing labels on product.

The labeler meets IP69K requirements and meets and exceeds IP66/NEMA4X standards to ensure consistent washdown performance. It’s capable of running up to 12-inch-wide labels. The adjustable angular peel plate is suitable for a range of applications. Separate unwind, drive, and rewind servo controls provide maximum control, stability, and performance.

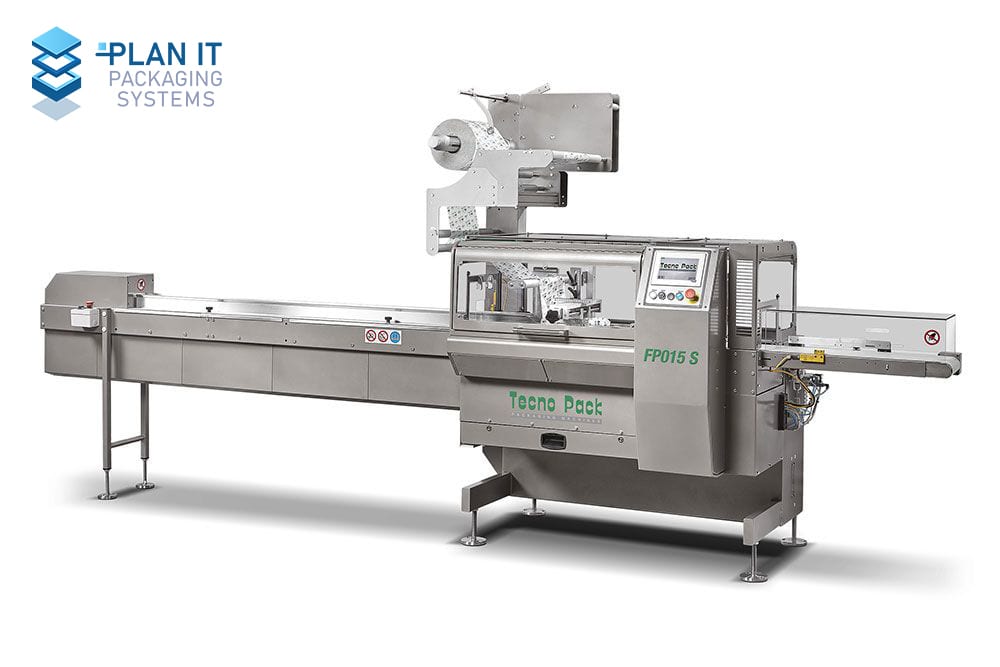

Pack 520 Flow Wrapper

Company: Plan IT Packaging Systems Inc.

Website: www.planitpackaging.com

Equipment Snapshot: The Pack 520 Servo Flow Wrapper is a versatile packaging machine for companies looking to optimize their packaging processes with a high level of production performance, up to 120 ppm. Plan IT Packaging Systems also offers fully automated feeding and flow wrapping systems up to 1000 ppm.

Equipment Snapshot: Featuring a new CXE integrated display controller, smart diagnostic tools and intuitive time-saving components, this system is capable of delivering up to 250 bags per minute (bpm) with wastage as low as 0.1 percent, alongside enhanced serviceability.

The simplicity of the new tna robag 3e VFFS packaging solution makes it easy to operate, service, and maintain. Featuring EtherCAT real-time protocol and an integrated display controller system, this latest tna robag reduces cabling infrastructure by 20 percent, enabling easier servicing and lower total installed costs.

The new system shares common core components with tna roflo distribution conveyors and the tna intelli-flav seasoning system, reducing the need for additional spare parts stocking. It features integrated LED lighting in the packaging jaw area to make maintenance safer and easier to perform. Equipped with smart diagnostics and remote connectivity, the tna robag 3e also offers real-time communication and status updates, enabling faster global servicing support.

November 2021 | Volume 4 | Number 4