New Products

Ingredients

cannabis products

Packaging

Table of Contents

Equipment

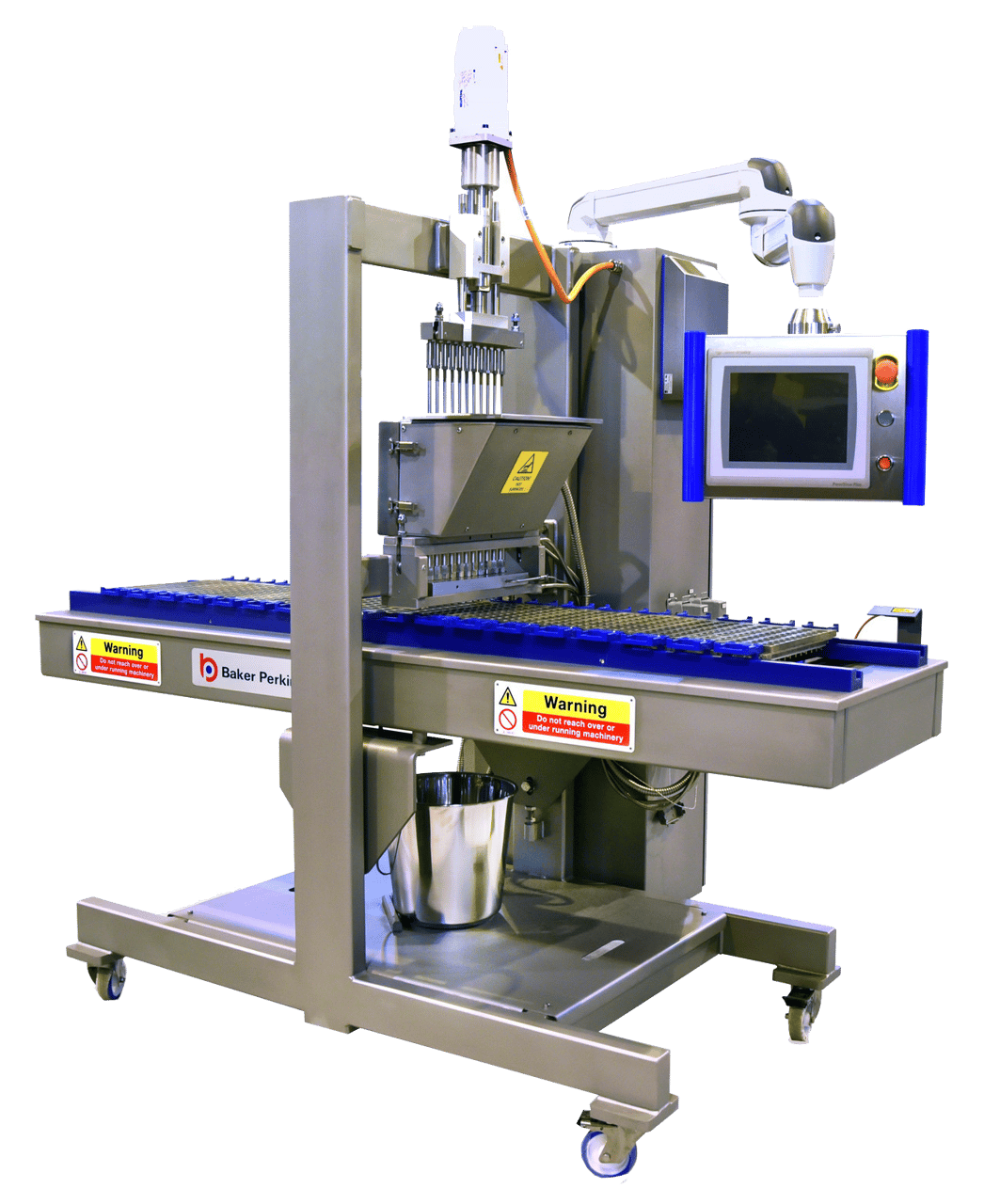

Equipment Snapshot: Baker Perkins Inc. has launched Infusent, an infused food equipment brand specializing in creating solutions and scalable equipment to support the infused product industry.

The Infusent ServoForm Mini is a servo-driven, short-run depositing system designed for entry-level operations or experimental and development work in more extensive operations. It can produce deposited candies, gummies, jellies, toffees and lollipops at piece weights ranging from 2 g to 16 g. The ServoForm Mini has hygienic design, making it ideal for production in the medicated markets.

Infusent starchless depositing technology is particularly suitable for healthcare products, where validation of the process is required. Dosing is consistent and repeatable, there is no recycling of starch, and the equipment is hygienic and easily cleaned.

The small footprint, low energy costs, and elimination of starch significantly reduce production costs compared with conventional starch molding processes. Low scrap rate, quick product changeovers, and continuous processing mean a rapid payback is assured.

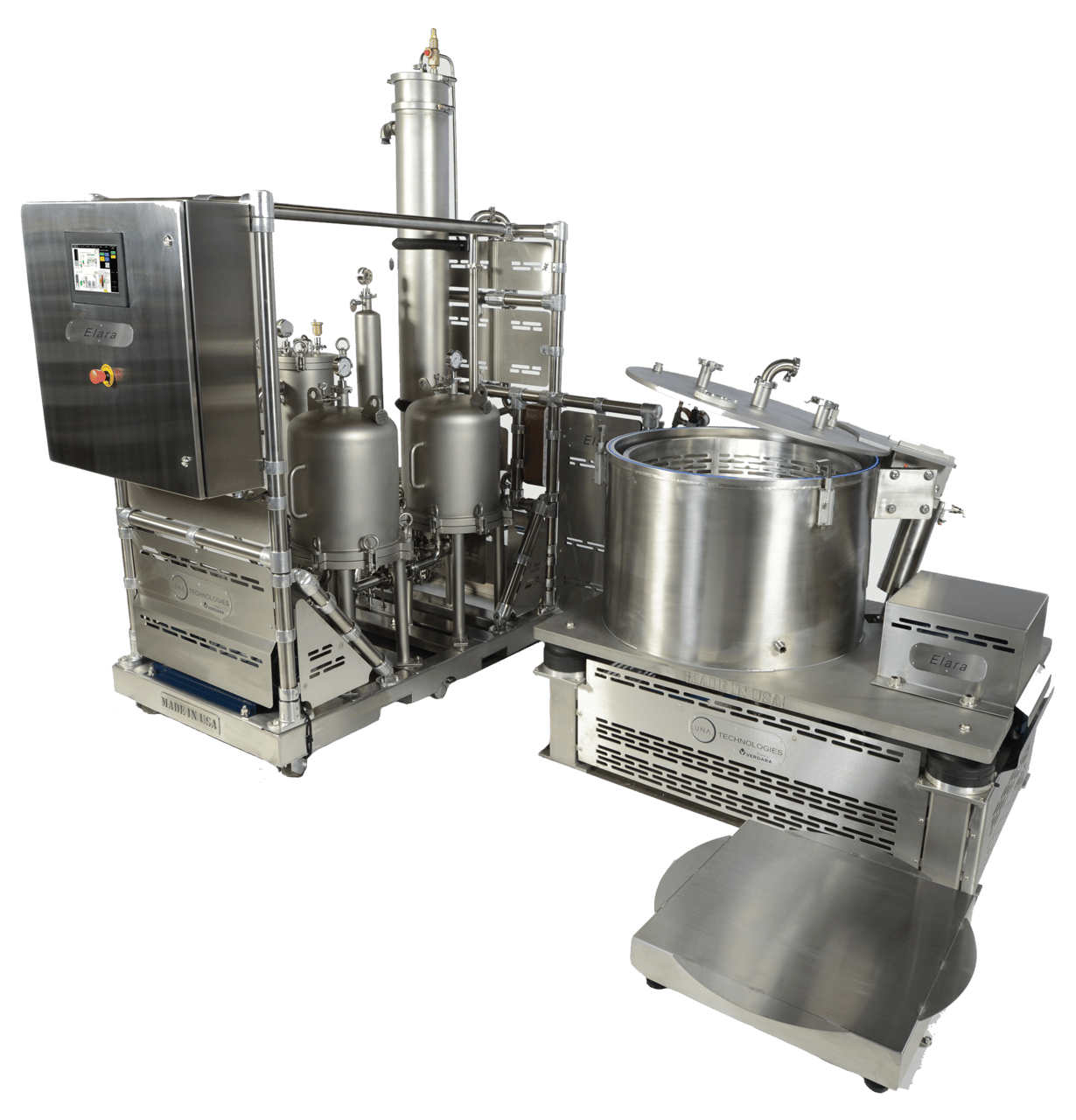

Equipment Snapshot: The Elara is an automated ethanol-based cannabis extractor for high-volume producers featuring low-temp cryo extraction technology developed with Verdara Technologies, an engineering and manufacturing company of cannabis and hemp extraction equipment.

The Elara extraction system combines three traditionally separate and manually operated processing steps into one fully automated process. This enables operators to load dried cannabis biomass into a single machine to produce refined concentrated oil through cryogenic extraction without any additional manual operations. In total, the system increases safety, improves quality, lowers costs, and reduces the overall equipment footprint.

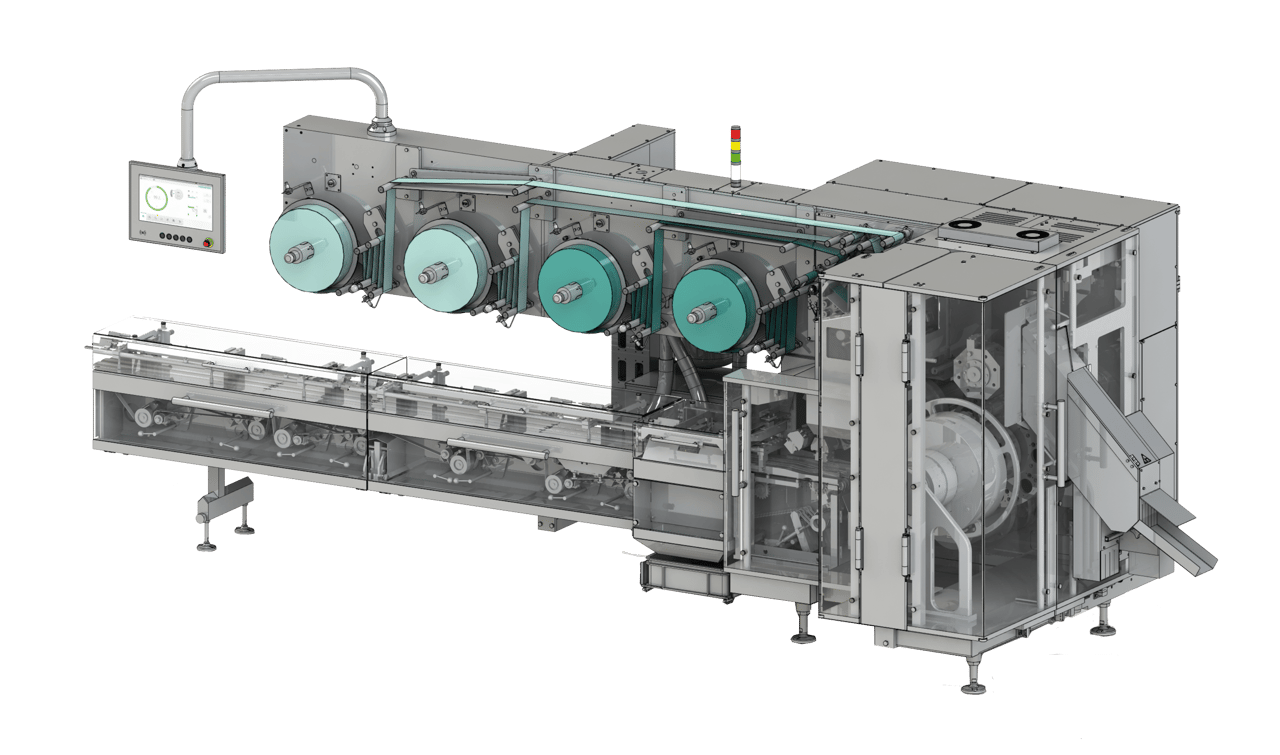

Equipment Snapshot: The CHS modular high-performance packaging machine was developed to gently package chocolate products. In 2020, Theegarten-Pactec optimized the machine for double-twist wrapping, achieving an output of up to 1,800 products per minute in the process.

The CHS is flexible in the wrapping styles it can handle: double twist, protected twist, top twist, side twist, foil wrap, bottom fold, side fold, Vienna fruit fold and envelope fold. The machine allows the wrapping style and format to be switched in four hours, and most require only one person. The new system offers lengths between 16 and 60 mm and widths between 12 and 35 mm.

X-Series Inline Ultra-High Shear Mixer

Company: Charles Ross & Son Company

Website: mixers.com

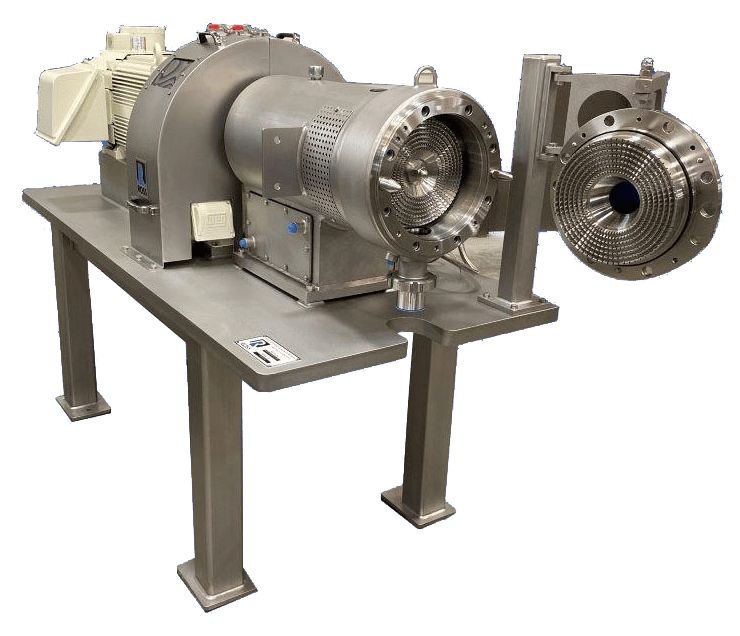

Equipment Snapshot: The Ross X-Series Inline Ultra-High Shear Mixer is designed for efficient high-throughput emulsification, dispersion, and homogenization. Available in both sanitary and industrial configurations, this versatile machine produces dispersions, suspensions and emulsions for a variety of industries, including food and pharmaceutical manufacturing.

The X-Series mix head is a patented design made up of concentric rows of intermeshing teeth. The product enters at the middle of the stator and travels outward through the radial channels. Every pass through the rotor/stator exposes the product to high shear due to the combination of tight tolerances and high tip speeds. Compared to traditional colloid mills, the X-Series routinely achieves a higher reduction in droplet or agglomerate size.

The Model HSM-409XSHD-125 is a CIP-capable sanitary mixer featuring a type 316 stainless steel mixing chamber, a 150-psig jacket for cooling and heating up to 250 degrees Fahrenheit, and an X-5 Series 9-inch diameter AL6XN stainless steel rotor/stator that operates up to 5700 rpm (13,430 feet/min tip speed).

Equipment Snapshot: Tri-Clamp Mount Mixers produce ample shear to form emulsions when mixing lipophilic compounds like CBD and other cannabis products. Designed for sealed applications, the sanitary tri-clamp design provides quick and easy, no-tools access to the vessel.

The Model TCM-3-050V electric variable speed unit plugs directly into a standard 120-volt outlet, providing out-of-the-box productivity. Standard features include a 3-inch diameter tri-clamp flange, internally mounted mechanical seal rated full vacuum to 125 psi, and a flexible shaft coupler.

A ½ HP epoxy coated washdown motor is driven by a Leeson Washguard NEMA 4X control and provides output speed from 35-1750 rpm to put cannabis compounds in emulsion. The ⅝-inch diameter by 35-inch long shaft attaches to the coupler and two 4-inch, 3-blade square pitch propellers with set screws. All wetted parts are 316 stainless steel, with optional electropolished wetted parts available.

MARCH 2022 | Volume 5 | Number 1