New Products

Ingredients

cannabis products

Packaging

Table of Contents

Equipment

Manufacturers must work with OEMs to develop individualized solutions.

By Alyse Thompson

Flexibility critical component of cannabis food and beverage manufacturing equipment

When it comes to manufacturing and packaging equipment, flexibility is key for creating quality cannabis-infused food and beverage products.

PMMI, the Association for Packaging andProcessing Technologies, notes in its report, “Cannabis Market Update: Unique Packaging Challenges for THC and CBD Products,” manufacturers must work closely with original equipment manufacturers (OEMs) to develop solutions that suit their individual requirements.

“New machine designs will need to be both flexible and adaptable, especially when it comes to the size and cost of the machine,” the report reads. “Cannabis companies range from small outfits with little capital and room to spare, to large production operations capable of making an investment in multiple machines at one time. OEMs will need to beaware of this range and work with cannabis companies to understand their needs and means and tailor machines to meet specifications.”

These small cannabis companies often start with pilot or laboratory equipment, since it can be used in both product development and manufacturing processes. Small-scale equipment can also fulfill production demand until the company outgrows it.

That includes high-shear mixing equipment, which is a critical step in many cannabis food and beverage manufacturing processes, says Christine Banaszek, sales manager, Charles Ross & Son Company, Hauppauge, NY.

“Investing in a scalable laboratory mixer is a game-changer,” she says. “Clients new to the cannabis space are pleasantly surprised that they can acquire a scalable laboratory high-shear mixer quickly and affordably. It's an entry-level machine that helps small labs and businesses create various formulations with a clear path to scale-up when the time comes.”

Admix, Inc., Londonderry, NH, relaunched its RS-02 Pilot Scale Mixer last year with a new mobile lift stand, making it easier to move the mixer—which fits through standard doorways— between laboratory spaces and production areas.

“We are pleased to bring the redesigned RS-02 pilot-scale mixer to processors looking for a high-shear mixer for smaller batch applications,” says Patrick Lakin, national sales manager, Admix. “Customers can quickly produce trial flavors or adjust formulations, helping them get their products to market faster.”

Speed and space considerations also play into running nimble operations. PTL, Auckland, New Zealand, provides chocolate and bar manufacturing equipment to the North American market. Last year, the company introduced the Melter V20, a chocolate melter that has a 45 percent smaller footprint and a melt rate that’s 125 percent faster than the company’s other melters. The machine also allows for quick changeovers, says Nick Halliday, managing director.

‘’Changeovers are an area that restrict production efficiency and the ability of our customers to be flexible, so we’ve addressed that in the V20 by transforming the changeover process,” he says. “Masses/coatings can be quickly switched and wash down is fast and simple, with a focus on allergen cleanability. For example, all product contact surfaces are removable or accessible for cleaning.’’

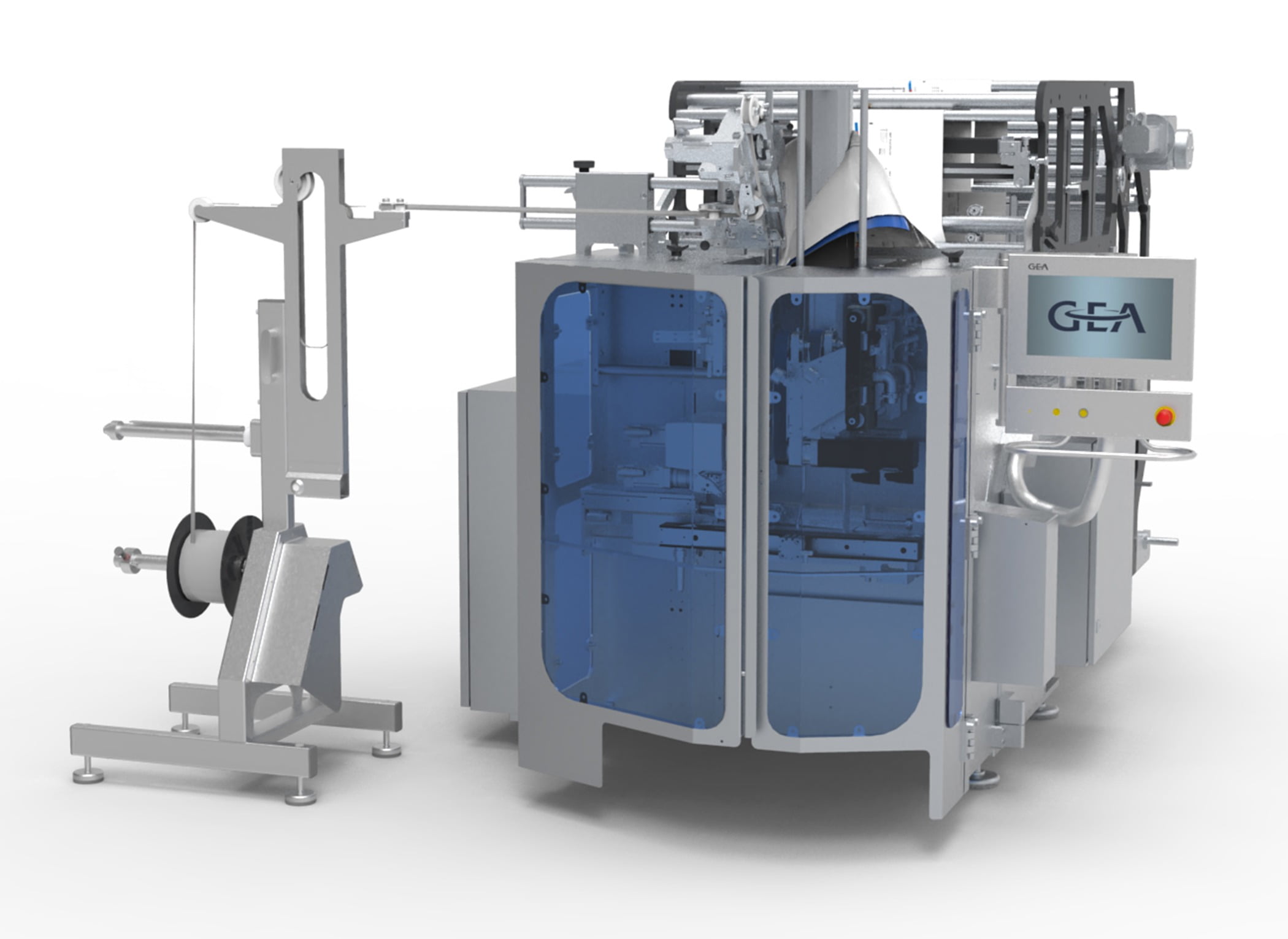

Flexibility is also critical in the packaging phase of manufacturing. GEA’s newest vertical packaging machine, the SmartPacker CX400 D-Zip, was designed to check a variety of boxes, says Martijn van de Mortel, product manager, vertical packaging, GEA, Dusseldorf, Germany.

“The SmartPacker CX400 D-Zip is future-ready,” he says. “Whether the need is for high quality, more capacity, greater flexibility, a small footprint, low maintenance, or a combination of all of these, the SmartPacker CX400 D-Zip answers the call. It’s capable of producing all common bag types on a single machine without compromising any expectations.”

“Customers can quickly produce trial flavors or adjust formulations, helping them get their products to market faster.”

Introduced in October 2020, SmartPacker CX400 D-Zip creates all existing bag styles and has a changeover time of under 45 minutes—without the use of special tools. Suitable for confectionery, snacks, and other products, the machine has an output of 100 D-Zip bags per minute.

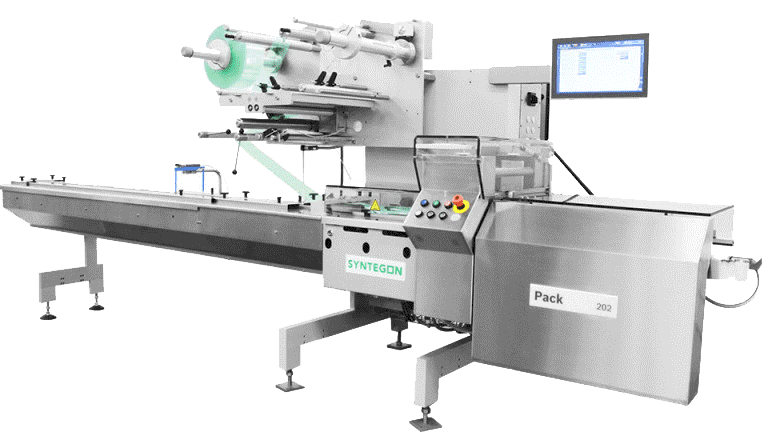

Flow wrappers, which wrap products in plastic film and typically have a horizontal orientation, must also support manufacturers in quick, easy production. Launched in August, Syntegon’s Pack 202 includes technological advances such as an easily removable discharge belt, upgrades to the cross-seal and fin seal units, and a highly intuitive, user-centered design.

“The machine is easy to operate, clean, and maintain, which reduces downtime and maximizes overall equipment effectiveness,” says Kelly Meer, product manager, Syntegon, New Richmond, WI.

No matter which type of product they’re creating, cannabis manufacturers must adapt to changes in demand and the industry, and flexible equipment and strong relationships with OEMs will make it easier.

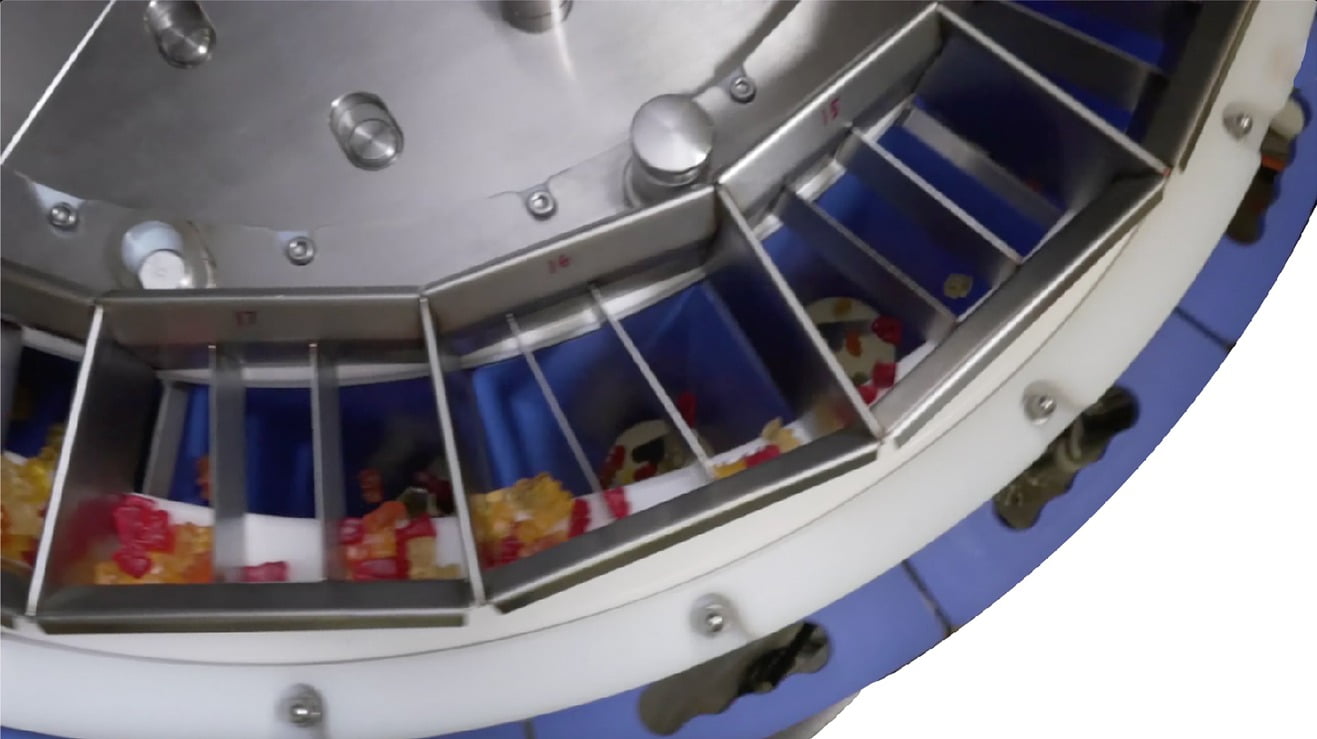

Multiple proprietary streaming mechanisms work together to achieve high-speed, accurate fills. First, gummies are deposited from a multihead weigher into a slide ring pocket with dividers to ensure the gummies are separated for streaming. Next, gummies are streamed into funnels by a slide plate. Shaped like a wedge, this plate ensures the gummies fall into the funnels without clumps, one-by-one. Lastly, any smaller product clumps are separated by a funnel baffle that prevents bridging before gummies are deposited into the container.

Together, the multihead weigher, Spee-Dee rotary filler and proprietary gummy streaming technology can fill up to 180 containers per minute.

Gummy Filling System

Company: Spee-Dee Packaging Machinery

Website: www.spee-dee.com

Equipment Snapshot: This high-speed, sanitary gummy filling system integrates a variety of multihead weighers and includes a Spee-Dee rotary filler and proprietary gummy streaming technology. The technology uses several patent-pending features that, when combined, help stream gummies one at a time to accurately fill bottles of various sizes.

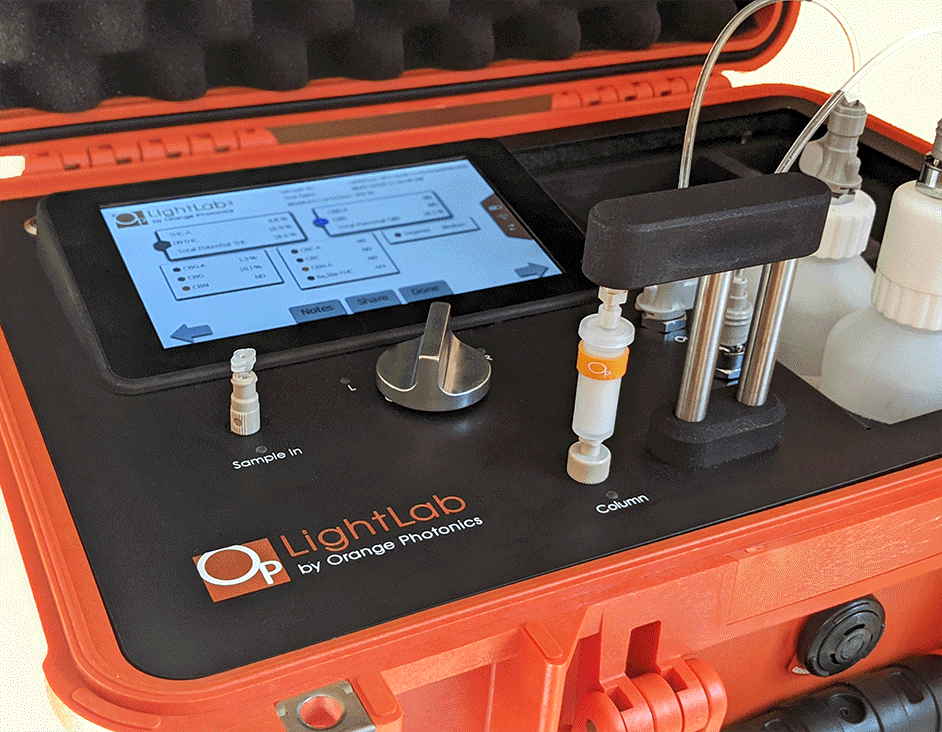

In addition to seven standard cannabinoids and total terpenes, LightLab’s optional Minors Module measures CBN-A, CBC-A, CBC, and Delta-6a,10a-THC, four rare cannabinoids valued by those pursuing additional product differentiation.

LightLab’s intuitive touchscreen interface relays step-by-step instructions allowing users to accurately determine cannabinoid content in a plant or plant-derived product in under 11 minutes. Rugged and portable, LightLab weighs just 13.5 lbs. and has an eight-hour battery life.

LightLab3

Portable HPLC Analyzer

Company: Orange Photonics

Website: www.orangephotonics.com

Equipment Snapshot: The LightLab 3 high-performance liquid chromatography-based (HPLC) analyzer can measure 11 cannabinoids, including THC and CBD, in cannabis plants and products down to a detection threshold of 0.05 percent.

A mobile skid allows these machines to be used anywhere in a plant, saving time and money by eliminating the need for multiple mixers separately dedicated to each vessel or product. Easy to clean in place and relocate, the pictured ROSS Model HSM-410 Inline High Shear Mixer is a versatile machine capable of handling different applications with viscosities up to 20,000 cP.

A VFD or control panel may be mounted to the cart and wired to the mixer motor for complete portability. Sanitary models are available with tri-clamp inlet/outlet connections and a one-piece stator/chamber cover for even quicker disassembly and clean-up. Ultra-high shear designs are offered as well.

Mobile Inline High-Shear Mixers

Company: Charles Ross & Son Company

Website: www.mixers.com

Equipment Snapshot: ROSS Inline High-Shear Mixers accelerate mixing, emulsification, and homogenization in both recirculation and continuous modes.

RS-02 Pilot Scale Mixer

Company: Admix, Inc.

Website: www.admix.com

Equipment Snapshot: Ideal for pilot plants and small-scale production, the Admix RS-02 high-shear pilot scale mixer can aid product development, formula optimization, trial mixtures, and small production runs.

The RS-02 includes a mobile lift stand with a wide base for added stability and a large hand crank to easily adjust mixer height. The portable unit fits through standard-width doorways, making it easier to transport it within a plant’s product development test labs and production areas.

The RS-02 has a batch capacity of 5-20 gallons (19-75 liters) and incorporates the Admix patented Rotosolver high-shear mixing impeller. Its patented design is engineered to provide balance between shear and flow so mixtures are completely homogenous, emulsified, and agglomerate-free in under 10 minutes.

The analyzer’s simple interface and intuitive operation make it easy for plant operators to make reliable measurements with little or no training. No sample preparation or harsh chemicals are required, and calibrations can be made from as few as five samples in minutes.

With a rugged polycarbonate design and compact footprint, the QuikTest analyzer can be set up almost anywhere, ideal for busy factories so that sampling and results are close to production.

The QuikTest comes with either a standard static or rotating sample stage for non-homogeneous samples. Additional sample accessories are available, including disposable petri dishes and disposable polymer bags for easy sample handling with no cleanup.

QuikTest At-Line Analyzer

Company: Process Sensors Corporation

Website: www.processsensors.com

Equipment Snapshot: The QuikTest analyzer performs rapid at-line analysis of moisture and oil content of ingredients, in-process samples, and final products for quality control. Designed for use on the production floor, the QuikTest measures moisture and/or oil from solid, powdered or paste samples such as coffee, cookies, snack foods, hummus, and cannabis to ensure the utmost efficiency in their manufacturing.

PTL Melter V20

Company: PTL

Website: www.ptlmachinery.com

Equipment Snapshot: The PTL Melter V20 offers greater power and flexibility with a 45 percent smaller footprint. Its self-contained, plug-and-play design allows the V20 to easily fit into any production area. It eliminates the need for a tank/kettle strategy and for long pipe runs, as it can be situated next to use-point.

The melt rate is 125 percent higher than the company’s previous melters. PTL has also transformed the changeover process, allowing for masses and coatings to be quickly switched. Washdown is quick and easy.

Designed to melt multiple SKUs, manage allergens and minimize downtime, the Melter V20 is the result of research with multinationals and co-manufacturer customers throughout the U.S. and other markets and intense R&D by PTL’s expert team.

The Pack 202 now features an improved canting mechanism. At the turn of a knob, operators can tilt the fin modules and adjust them easily for tighter or looser packs. The standard double-spring kit also offers more consistent and stable seals, while the adjustment resolution has been doubled, thus enabling more precise and repeatable crimper adjustments.

Syntegon has now equipped the Pack 202 in North America with a standard 450-millimeter dual backstand. Depending on brand owners’ needs, a 650-millimeter single backstand is also available.

As a new option for North American customers, the Pack 202 can be equipped with a one-meter-long reject belt. Its short length offers brand owners a much smaller machine footprint compared to the previous Pack 201 machine. The upper section of the reject belt is easy to remove for quick belt changes and cleaning processes. The detection function on the short discharge belt rejects faulty packages and automatically ejects them using compressed air. For larger and heavier products, a two-meter-long discharge module with reject plow is available as an option.

Pack 202 Flow Wrapper

Company: Syntegon

Website: www.syntegon.com

Equipment Snapshot: The Pack 202 is a fully-automated horizontal flow wrapping machine for low to medium speeds. It’s suitable for bars, bakery products, confectionery, cookies, and crackers, as well as non-food applications. With the Pack 202, manufacturers benefit from an easily removable discharge belt, upgrades to the cross-seal and fin seal units, and a highly intuitive, user-centered design.

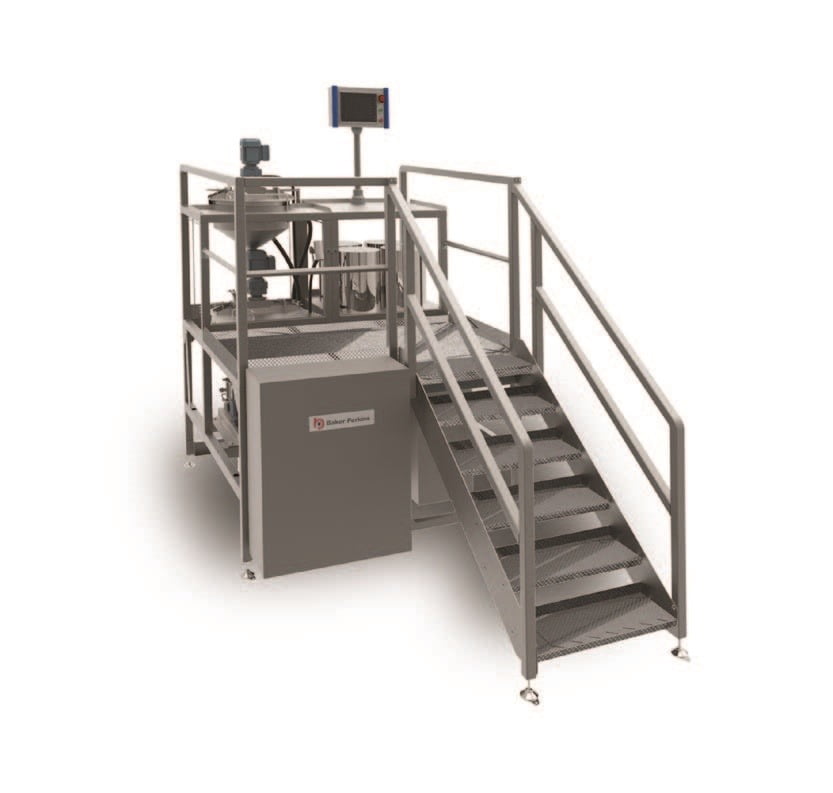

JellyCook Batch Cooker

Company: Baker Perkins, Inc.

Website: www.bakerperkins.com

Equipment Snapshot: Baker Perkins’ JellyCook is a flexible batch weighing, mixing, and cooking system for pectin and gelatin confectionery syrups. The system consists of an oil-heated stainless steel cooking vessel with a variable speed mixer/stirrer, a reservoir tank, and a support frame with operator platform.

The cooker is mounted on load cells, allowing the control system to monitor the addition of major ingredients. An intelligent, adaptive control system uses on-screen prompts to guide the operator through the process of preparing a batch. Active ingredients are added to the weighed batch at the end of cooking to ensure accurate dosing control. A standard, semi-automatic JellyCook cooker produces 30-kg batches, with an output of up to 50 kg/hour.

Scrapers mounted on the mixing assembly ensure product is moved away from the vessel walls, ensuring even cooking and preventing burn-on.

Mounted below the cooker vessel is a 45-kg reservoir tank. This stainless steel vessel holds the cooked product at a specified temperature to ensure it is easily transferred to the depositor. At this stage minor ingredients can be added manually and incorporated into the batch using the built in stirrer. From the reservoir tank the product can either be automatically pumped to the depositor or taken manually.

All modules work without chains. In addition to increased food safety, the chainless line design lowers the maintenance efforts. Generally, cleaning time per module is only 30 minutes because there are no installations underneath the depositing sections.

The process keeps thermal consistency at an ideal level, including the transition to packaging. The smart buffering reacts to the packaging output, so ChocoX can keep running even during a stop in the packing process. The fully-automatic mould handling system further increases the line’s efficiency.

ChocoX Chocolate Moulding Line

Company: Bühler Group

Website: www.buhlergroup.com

Equipment Snapshot: ChocoX combines flexibility and agility in production and hygienic design, resulting in significantly lower operational costs. Its modular design allows for unlimited crossovers and quick adaptation to different products. Every function is placed in an independent module to be freely adapted for the production process customers need. In under 30 minutes, chocolate producers can change a module.

Vertical SmartPacker

CX400 D-Zip

Company: GEA

Website: www.gea.com

Equipment Snapshot: This easy-to-use vertical bagger combines fast, high-quality operation with maximum flexibility and uptime to produce D-Zip packaging for both retail and food service use. It’s suitable for candy, nuts, frozen fruits, and many other products.

The SmartPacker CX400 D-Zip integrates a newly developed corner seal unit, designed to reduce complexity and improve quality, flexibility, and serviceability. It also features an output of up to 100 D-Zip bags/minute in a small footprint.

The SmartPacker CX400 D-Zip has a changeover time of under 45 minutes without the use of special tools and features front discharge.

Alyse Thompson is managing editor of Cannabis Products

March 2021 | Volume 4 | Number 1