New Products

Ingredients

cannabis products

Packaging

Table of Contents

Equipment

Equipment Snapshot: The nano GEN2 i4.0 range of nitrogen gas generators generate nitrogen gas on-site at 99.5% – 99.9% purity, suitable for cannabis packaging to extend product freshness.

With a nano GEN2 i4.0 gas generator, a packager can expect payback typically between 6 to 24 months. This unique modular design and energy saving functionality offers significant advantages over delivered gas options as well as traditional generator designs.

The compact system can be installed easily and requires only a pre-treated compressed air system to start production.

Equipment Snapshot: The 4SC-235 compact premade pouch machine, made at Viking Masek’s headquarters in Wisconsin, has the following features:

- Stress-tested bag grippers: Final testing included running the assembly through 1.5 million cycles.

- Combined functions to decrease space: Multiple machine functions are combined into a single assembly, allowing for a more compact design and decreased material cost.

- Streamlined infeed: A stacked infeed was designed that allows an operator to easily load up to 1,000-plus bags at a time and then walk away until the magazine needs to be refilled. This means minimal training is needed to load the machine.

- Simple changeover: Machine adjustments are easily completed and repeated without tools or a high level of technical knowledge, making it easier for casual operators to run the machine successfully. Also featuring manual bag width, length, and height adjustments, changeover to different size bags is quick, simple, and requires minimal skill. Visual indicators also reduce operator training issues due to language barriers.

- Simplified interface: The HMI (human machine interface) has been programmed from scratch to be greatly simplified.

- Minimal maintenance: When parts need to be replaced, they can be 3-D printed at Viking's U.S. headquarters or sourced locally.

Equipment Snapshot: ROSS Batch High Shear Mixers equipped with the Solids/Liquid Injection Manifold (SLIM) Technology deliver powders in an efficient manner for quick wet-out and complete dispersion into low-viscosity liquids.

In a conventional rotor/stator mixer, materials are continually drawn from below the mixing head and then expelled at high velocity through the stator openings. A SLIM mixer assembly with Progressive Spiral Porting creates a powerful vacuum that draws powders directly into the high-shear zone and rapidly disperses individual solid particles into the liquid vehicle. This method of powder addition dramatically reduces the formation of lumps (fisheyes), prevents floating powders, eliminates dusting, and accelerates mixing time. The SLIM can also be used to introduce minor liquid components and create fine emulsions.

To easily raise and lower the high shear mixer in and out of the mix vessel, Ross offers a floor-mounted design equipped with an air/oil hydraulic lift. Safety limit switches prevent operation of the mixer while in a raised position or without a mix vessel in place.

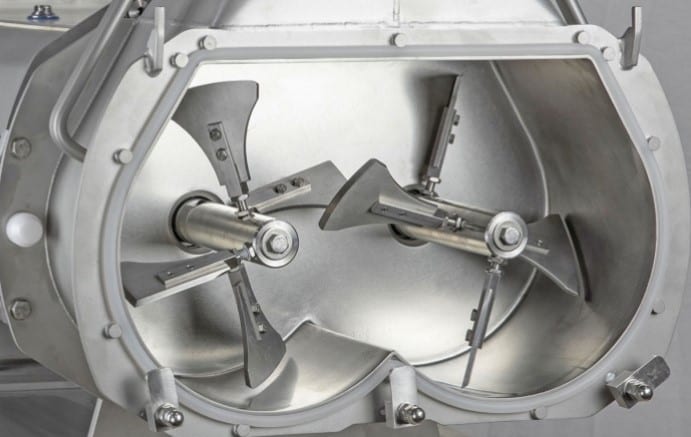

Multiflux GMS Laboratory Mixer

Company: Gericke Group

Website: gerickegroup.com

Equipment Snapshot: Applying the company's proprietary double-rotor design proven in its line of high volume mixers, the GMS Laboratory Mixer was developed to offer the same high speed, gentle, and hygienic mixing capabilities in a low volume, tabletop model.

While the existing lineup of batch mixers accommodates usable volumes up to 4,000 liters, the new laboratory batch mixer accommodates usable volumes from as low as one liter up to 20 liters for fast, repeatable mixing during new product development, formulating and testing, and other R&D tasks.

Expanding the Multiflux mixer line to seven models plus custom designs, the GMS Laboratory Mixer automatically directs the materials into a fluidized zone for fast yet gentle interactions that achieve a homogeneous mixture in cycle times of 30 seconds or less, even when mixing materials in small quantities below 0.01 percent. The benchtop mixer includes stainless steel construction as standard with a full-size access door for easy access to the mixing rotors, mixing chamber, and entire interior for safe, complete cleaning.

Equipment Snapshot: WIPOTEC-OCS has released a multi-function metal detection-checkweigher-vision module. The All-in-One Inspection Unit combines two quality assurance functionalities—X-ray foreign objects detection and precision checkweighing—with an enhanced vision system capable of verifying label placement, barcode legitimacy, film detection, and validation of expiration.

The All-in-One, which also includes an advanced reject system that sorts rejected products by pre-set categories, represents the first time WIPOTEC has combined so many inspection functionalities into one machine. Controlled by a single intuitive HMI, the unit is an attractive, space- and cost-saving option for both food and beverage and pharma manufacturers.

JUNE 2022 | Volume 5 | Number 2