New Products

Ingredients

Cannabinoid Distillates & Isolates

Equipment

Packaging

Ingredients

and consistent

Safe

The right cannabinoid ingredients are essential to developing safe, consistent infused foods and beverages.

By Douglas J. Peckenpaugh, Group Editorial Director

One of the most-important aspects of cannabis-infused food and beverage product development is consistency. With active ingredients like cannabinoids in the mix, cannabis consumers seek standardized, reliable levels of cannabidiol (CBD) and tetrahydrocannabinol (THC) in retail products—regardless of whether that product comes from a dispensary or a traditional retail outlet like a convenience or grocery store. Consumers need to know what to expect—both in terms of the intended physiological effect and incumbent health and wellness benefits.

“Beyond the well-known ‘major’ cannabinoids of THC and CBD, cannabis plants have more than 100 known cannabinoids, with many more being investigated,” says Austin Stevenson, chief innovation officer, Vertosa. The top 10 cannabinoids usually found in extracts are delta-9 THC, delta-8 THC, THCA, THCV, CBD, CBDA, CBDV, cannabigerol (CBG), cannabichromene (CBC), and cannabinol (CBN).

“Cannabinoids should be considered as functional ingredients,” says Stevenson. “Using them in foods and beverages is enabling product manufacturers to design new experiences.”

Cannabinoid oils are produced through several steps, notes Stevenson. “Once extracted from the plant, solvents are used to refine the product for the distillation phase. In the distillation phase, the cannabinoids may be separated, purified, and/or isolated to the desired components. Afterward, these components undergo a decarboxylation step and are then dissolved into pure cannabinoid oils.”

Water-dispersible cannabinoid products are created through oil-in-water emulsion, says Stevenson. “Not only can water-dispersible cannabinoids broadly diversify the use of cannabinoids in the food industry, but they also increase absorption rates in the body. This means consumers don't have to wait to feel the effects of cannabinoids, and you may innovate products that are fast-acting.”

Although there are myriad cannabinoid ingredients available for food and beverage developers today, they are very limited in their usage, suggests Barbara Shepherd, founder, Aseppak, Denver. “Distillates are probably the most common, which have a wide range of composition, potency, and physical characteristics.” She notes highly concentrated cannabinoid distillates can prove difficult to work with due to variances from batch to batch. And although isolates are easier to formulate with, they’re expensive.

“Having a clear understanding of the actual profile or purity of the ingredient allows for easy math in the formula,” says Shepherd. “But knowledge of the entire product is paramount to ensure the quality of the food or beverage to be infused.” She also recommends having a strong understanding of any potential ingredient interactions. “Successful product developers in this space must also understand the complications and mechanics of large-scale production of cannabis-infused products to ensure they are safe, consistent, and of the highest quality.”

Seeking stability

When it comes to cannabinoid ingredients, don’t ever believe that one size fits all, says Stevenson. “Creating infused food and beverage products is complex chemistry. For example, when trying to infuse a beverage, oil and water do not naturally mix. Therefore, you need a water-dispersible technology like an emulsion to suspend cannabinoid oils evenly.”

Choosing the best ingredient or technology often comes down to the other ingredients in the infused product, says Stevenson. “For liquid-based products such as beverages and gummies, liquid emulsions are a no-brainer. But for those who are looking to capitalize on broader mainstream wellness trends, powder technology may provide valuable versatility and flexibility. With this solution, product makers can address a much-wider set of product categories, from beverage enhancers to pressed tablets, fillable capsules, wholesale nutritional supplements, and more.” Baked goods and bars also respond well to powder-based ingredients, he says. “Depending on your desired ingredients, packaging, and manufacturing processes, you will likely require a specific formulation. An ingredient provider who is unwilling or unable to customize their technologies and solutions to fit your needs is unlikely to match your standards for quality and will be incapable of helping you develop new products with different requirements.”

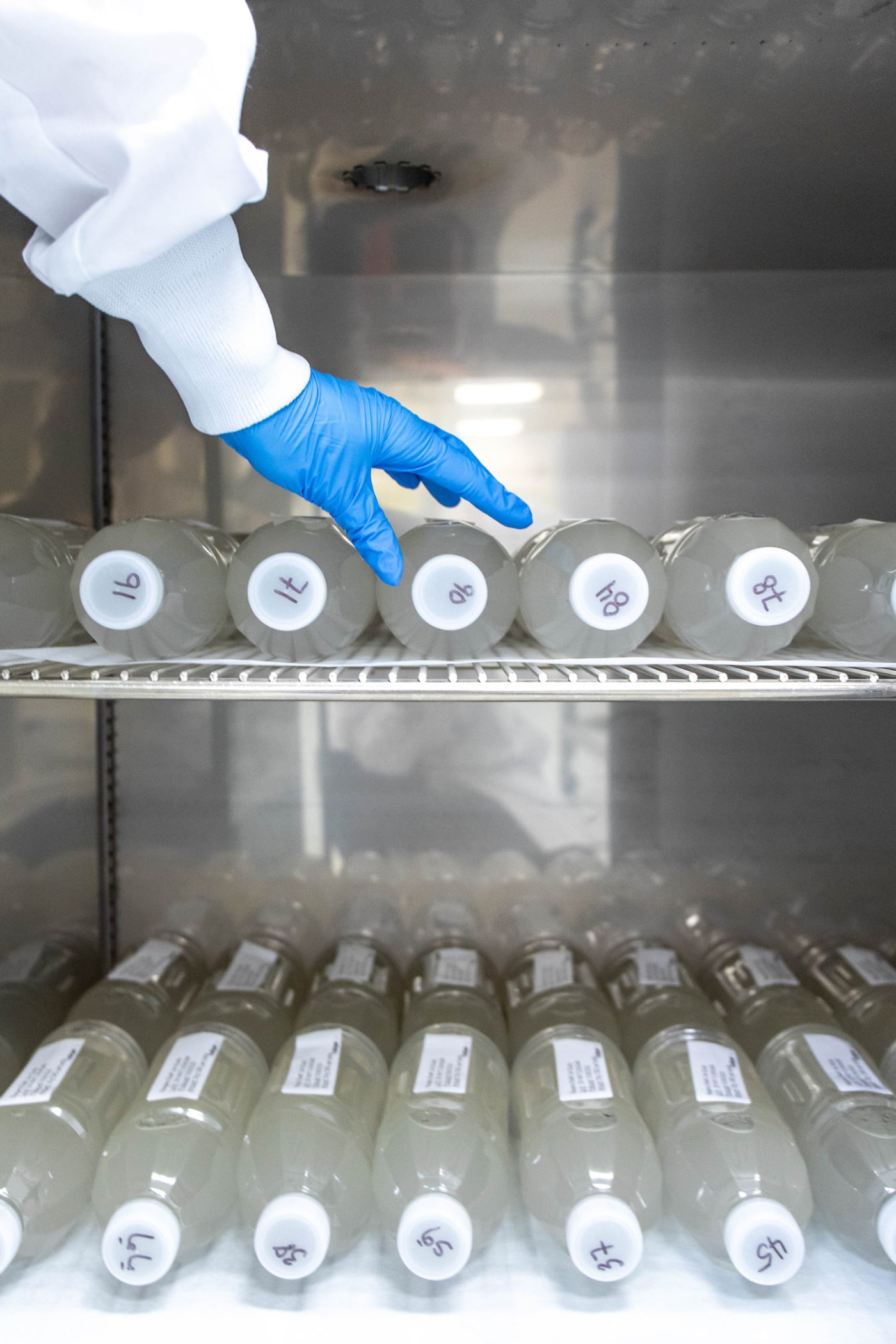

The most widely available cannabinoid ingredients are distillates and isolates, says Drew Hathaway, senior scientist, Caliper Foods, Commerce City, CO. “The potential issue with those ingredients is the cannabinoid content and flavor profile can vary greatly, which can make it challenging to create a consistent infused food or beverage product unless you have close relationships with your suppliers.”

Solubility is a top challenge. “Since cannabinoids are naturally fat-soluble compounds, they are incompatible with certain products, such as infused beverages,” says Hathaway. That’s why Caliper’s ingredients business converts distillates and isolates into water-soluble liquids and powders that can be used to infuse a wider variety of products, including ready-to-drink beverages.

“The main benefits of using distillates and isolates is that they can be highly controlled in the supply chain to ensure consistency—if manufactured properly,” says Hathaway. “This is important when creating infused food products that aim to deliver predictable results to consumers time and time again.” He goes on to note that isolates, including those for CBD, CBG, CBN, and CBC, typically have cleaner flavor profiles and are less likely to contribute characteristic cannabis flavors to the final product compared to distillates.

Hathaway notes Caliper Foods has been able to prove through human-based clinical research with Colorado State University that its water-soluble CBD ingredients are faster-acting and have significantly better bioavailability compared to oil-based cannabinoid ingredients.

“THC-free broad-spectrum distillates are commonly used in the CBD industry to deliver high levels of CBD, along with other minor cannabinoids and terpenes to provide the ‘entourage effect’ for the final consumer,” says Hathaway. “However, CBD and many other minor cannabinoids such as CBG, CBC, and CBN are also available as highly potent isolates.” He notes it’s becoming more common to combine specific ratios of multiple isolates to create custom, standardized, broad-spectrum products that can be reliably recreated.

A primary ingredient sourcing dynamic today centers on the THC level present in the product, notes Mark Elfenbein, chief revenue officer, Socati, Austin, TX. “Broad-spectrum and THC-free products are receiving more traction in 2021 due to the stigma around products that contain even legal limits of THC, which is below 0.3 percent present in the product.” When infused into a food and beverage, the typical bitter CBD taste can be masked and made more user-friendly, he notes, thereby providing a good way for new users to get an introduction to the benefits of CBD compared to more-traditional tinctures.

Water-dispersible CBD powder is getting a lot of traction recently in the form of stick packs ready to add to water, notes Elfenbein. Such products can be custom-flavored, as well incorporated with an array of functional ingredients, including ashwagandha, valerian root, chamomile, antioxidants, electrolytes, and vitamins, such as vitamin C, B, and D, he says.

“Isolates are the purest form of a specific cannabinoid, as they are typically more than 99 percent pure,” says Shepherd. “A major advantage of working with isolates is due to the purity. It is very easy to guarantee highly specific repeatability and consistency. However, isolates lack the ‘entourage effect’ that some consumers and product manufacturers prefer and can be found in broad- or full-spectrum distillates. These sorts of extracts have a diverse array of other cannabinoids, terpenes, and other naturally occurring compounds that contribute to the overall sensory experience.”

As technology of isolating cannabinoids progresses, more options are arising to purchase single molecular profiles, and scientists are finding techniques to segregate them on a daily basis, says Shepherd. “This allows for formulators to research, test, and build cannabinoid profiles that may mimic a specific strain, or promote a certain efficacy. Broad- or full-spectrum distillates can offer a broader range of cannabinoid profiles, but have a tendency to be limited to concentration, potency, and complexity. These shortcomings are controlled by the biomass from which they were extracted from, as well as the method of the extraction. The diffusion of cannabis biomass may not have the concentration of either distillates or isolates, but are able to catch a much wider range of cannabinoids, and have shown to create ingredients that have a profile that matches closely to the original biomass from which they came from, allowing for a more-natural product.”

Relationship building

When first investigating potential supplier relationships, ask a lot of questions, suggests Stevenson. “Ask for documentation. Certificates of analysis, safety data sheets, farm bill compliance, and other documentation ensures that you’re receiving the highest-quality product from an ingredient provider.”

Lack of compliance with documentation requirements means a supplier could face regulatory issues at any moment, potentially leaving the product developer at legal risk and unable to fill orders, says Stevenson.

Companies can help ensure their supply chain by employing a strong quality management system, says Shepherd. “We like to live by the saying, ‘Trust, but verify.’ Always verify incoming ingredients by submitting them to an ISO 17025 accredited laboratory for analysis. Store the ingredients according to their recommendations. Ask to see their quality manual, material safety data sheet (MSDS) documents, and any recent third-party audit reports.”

It’s extremely important to vet cannabinoid ingredient suppliers to ensure you’re receiving high-quality ingredients, says Hathaway. A cannabinoid ingredient supplier should be able to show its customers a certificate of analysis (COA) with third-party lab results showing minimal to no contamination levels of heavy metals, pesticides, and residual solvents in its ingredients.

“We also always recommend looking at COAs for multiple lots of the same product to evaluate the consistency of the supplier’s operation,” says Hathaway. “For larger companies, you’ll also want to ensure that your supplier has a large enough operation to supply sufficient quantities to suit your needs and can scale their operation to match your growth. Additionally, you want to ensure they have a well-established supplier-assurance program and at least understand basic food industry quality standards such a cGMP compliance.”

Opting for organic is another way to seamlessly build in transparency. “We typically recommend to source organic products due to the supply-chain transparency offered with such products,” says Elfenbein. Additionally, he recommends using suppliers who have strong food safety certifications, such as SQFI.

Image Source: Courtesy of Caliper Foods and Socati

June 2021 | Volume 4 | Number 2