New Products

Ingredients

cannabis products

Packaging

Table of Contents

Equipment

Equipment Snapshot: The CAPQ System from Verista leverages deep learning/AI for beverage bottle cap integrity and fill-level inspection. It uses software to recognize what a “good” capped bottle is supposed to look like and reduces false-rejects, saving on wasted material expense.

The CAPQ System, using real-time feedback on every bottle, knows what to keep on a line and what to reject. The 360-degree inspection detects cap placement, height and skew, tamper band integrity, fill level on clear and colored content while ignoring plastic shards and nibs and water droplets.

The system is ideal for high throughput environments and can inspect more than 1,000 bottles per minute. The stainless-steel unit fits easily over an existing conveyor for quick and easy line integration and offers recipe-driven automatic height adjustment.

The turnkey system, with a robust human-machine interface, has a low cost of ownership and reduces or eliminates bottlers’ dependency on bottle dryers. Plus, the system’s AI-based False Reject Suppression Technology lowers costs by reducing scrap and rejection.

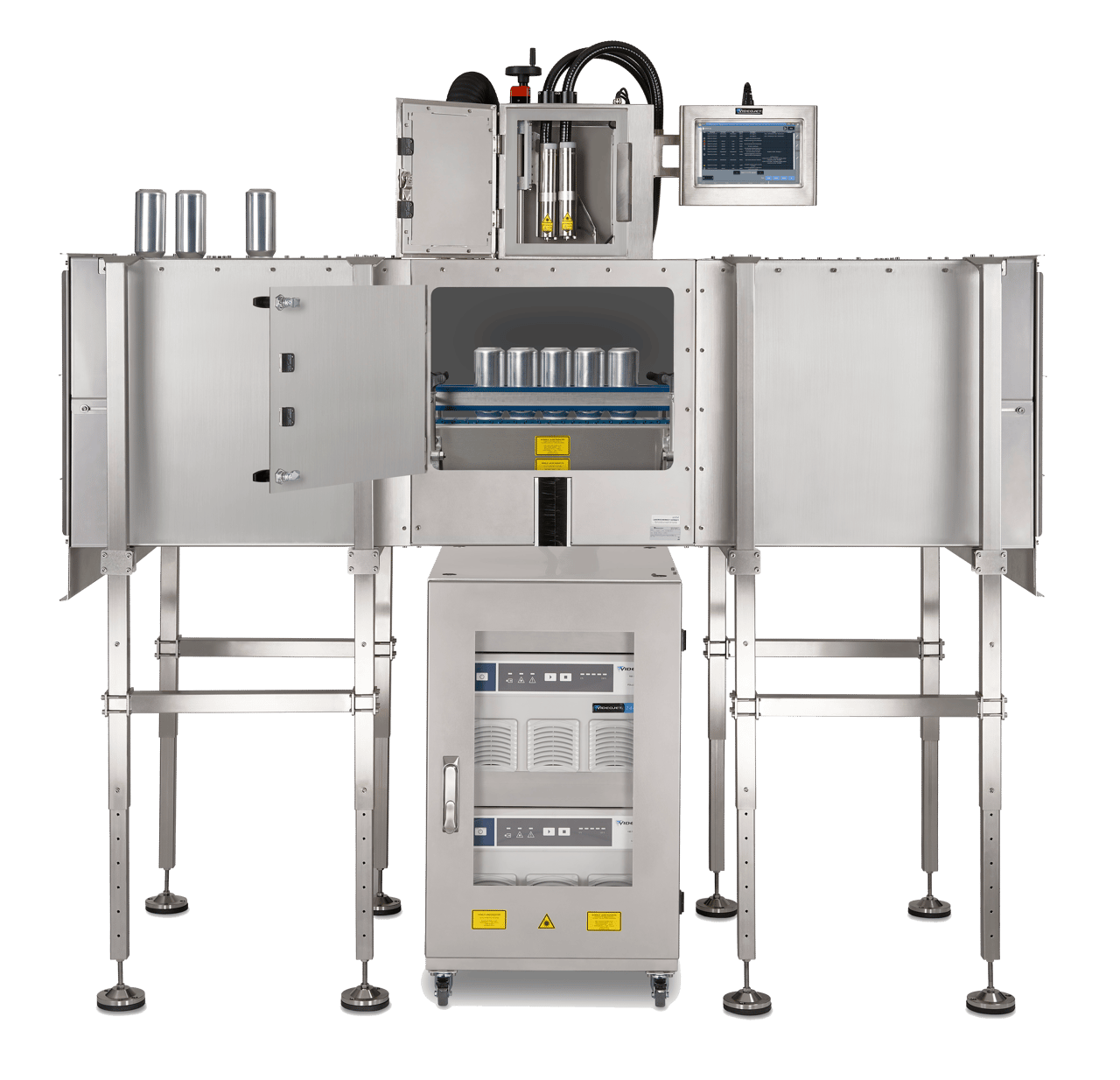

The Lightfoot canning solution includes IP69 rated marking heads and an IP65 rated supply cabinet that can easily handle humid, sugar-laden, or washdown environments. Featuring dual Lightfoot marking heads seamlessly integrated with one software control, the Videojet canning solution is able to reach marking speeds of up to 100,000 cans per hour.

The Lightfoot canning solution includes a class 1 sealed enclosure to eliminate optical radiation, while an integrated fume extractor keeps operators protected from harmful aluminum dust and fumes. A modular beam shield fits around conveyor belts for easy integration. The marking head air knife keeps the beam exit window clean of dust or dirt buildup.

Lightfoot Fiber Laser Solution

Company: Videojet

Website: www.videojet.com

Equipment Snapshot: This advanced laser canning solution combines the standard reliability of a Videojet fiber laser with the speed of dual Lightfoot marking heads to meet the demanding production needs of beverage canning manufacturers.

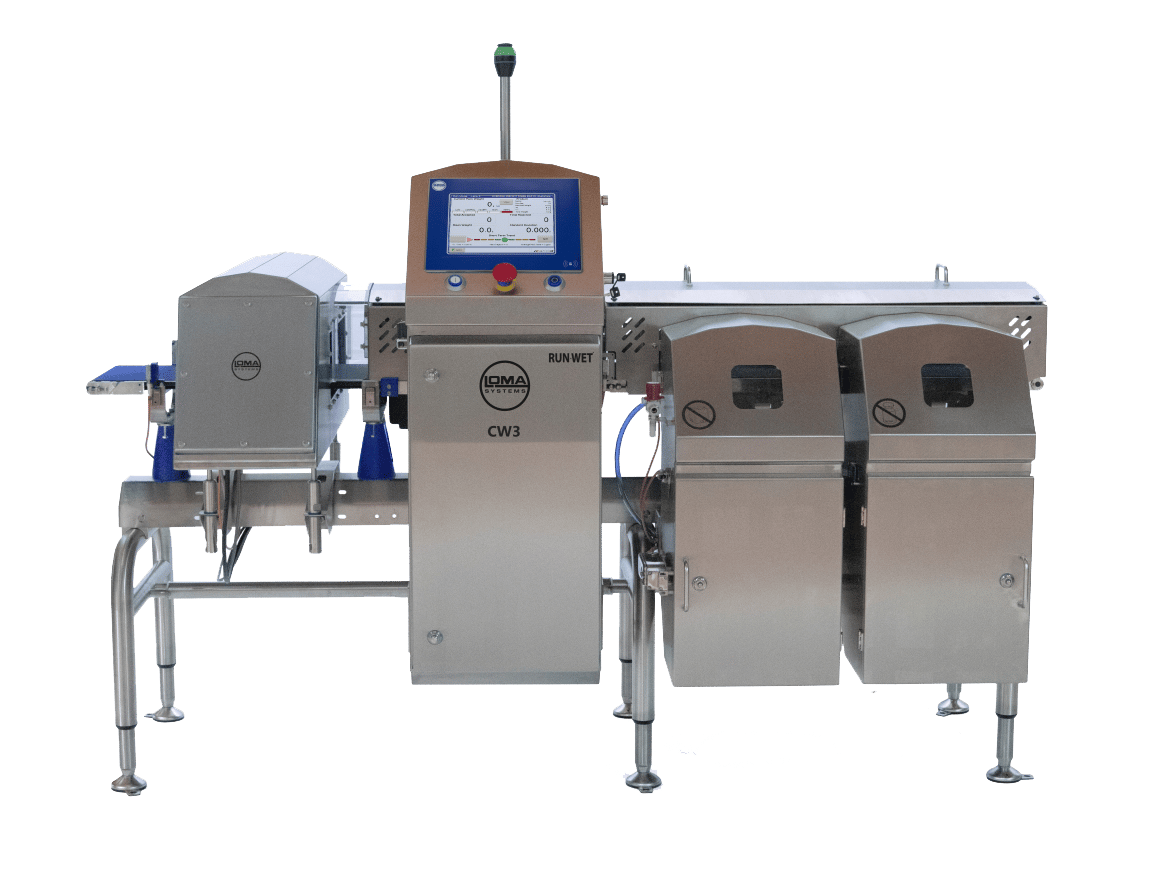

Equipment Snapshot: Designed for harsh washdown environments, the CW3 Run-Wet Combo and CW3 Run-Wet checkweigher systems are IP69 rated and designed to follow the latest industry leading principles for hygiene standards.

The combo provides a combined checkweigher and metal detector in one, and the checkweigher is a standalone checkweigher system. Created to withstand harsh, high-pressure and high-temperature deep-cleaning regimes, the systems are suitable for high-care food environments, such as protein, dairy, produce, meat, fish, convenience food, and more.

Sanizap Steam

Cleaning Technology

Company: Bayzi Corporation

Website: www.bayzi.com

Equipment Snapshot: SaniZap is designed to safely sanitize almost any surface, leaving no residue, moisture, or harmful chemicals. The process is suitable for following CDC guidelines that call for frequent sanitization.

Portable equipment is available in different models to accommodate a range of facilities and price points. The SaniZap-1 is a handheld unit, while the SaniZap-4 is a powerful, multipurpose cleaning tool on wheels that can be used at lower steam temperatures with soap or detergent to quickly clean visible dirt and grime and can also be used at higher steam temperatures for antimicrobial sanitizing.

Especially with high-priced active ingredients, it is important to fill small quantities flexibly and, if possible, without product loss. The piezo station makes this possible for quantities starting at 0.1 milligram filling weight.

The new Automated Process Development (APD) tool is also available for the GKF 60 to determine the optimum parameters for filling and automatically adjust them during the filling process. In addition, each dosing station can be optionally equipped with a gravimetric 100 percent weighing system for each component dosed.

The GKF 60 is available in either the standard version, the containment variant, or a combi solution. The newly developed changeover concept offers maximum flexibility. With exchangeable cabin elements and a cleaning concept up to WIP (washing in place), the combi solution can be adapted for both simple and highly potent formulations up to OEB5 high-containment in a few steps.

The separate control cabinet with integrated operator interface and particularly user-friendly dashboard provides further space savings.

GKF 60 Capsule Filler

Company: Syntegon Technology

Website: www.syntegon.com

Equipment Snapshot: The GKF 60 impresses with high flexibility and low space requirements. With only six stations, the machine is compact and requires fewer format parts.

August 2021 | Volume 4 | Number 3